Table of Contents

Has your business ever run out of stock when the demand was high?

Or have you experienced missing goods in the warehouse or quantity difference between stocktaking results and company records?

Or delayed delivery due to difficulty finding goods?

If your business has or even often experiences the problem above, it is a sign that you need to implement an inventory management strategy as soon as possible.

What is Inventory Management?

Inventory management or stock management is a management strategy to maintain, supervise, and control a business’s inventory, for example by controlling how many items must be ordered, stored in warehouses, and distributed, as well as its related costs.

Why should Inventory be Well Managed?

To ensure that the level of product inventory in the warehouse is always balanced, more precisely: balanced with the number of products sold.

If the amount of stock is too many, the risk of financial loss will be higher.

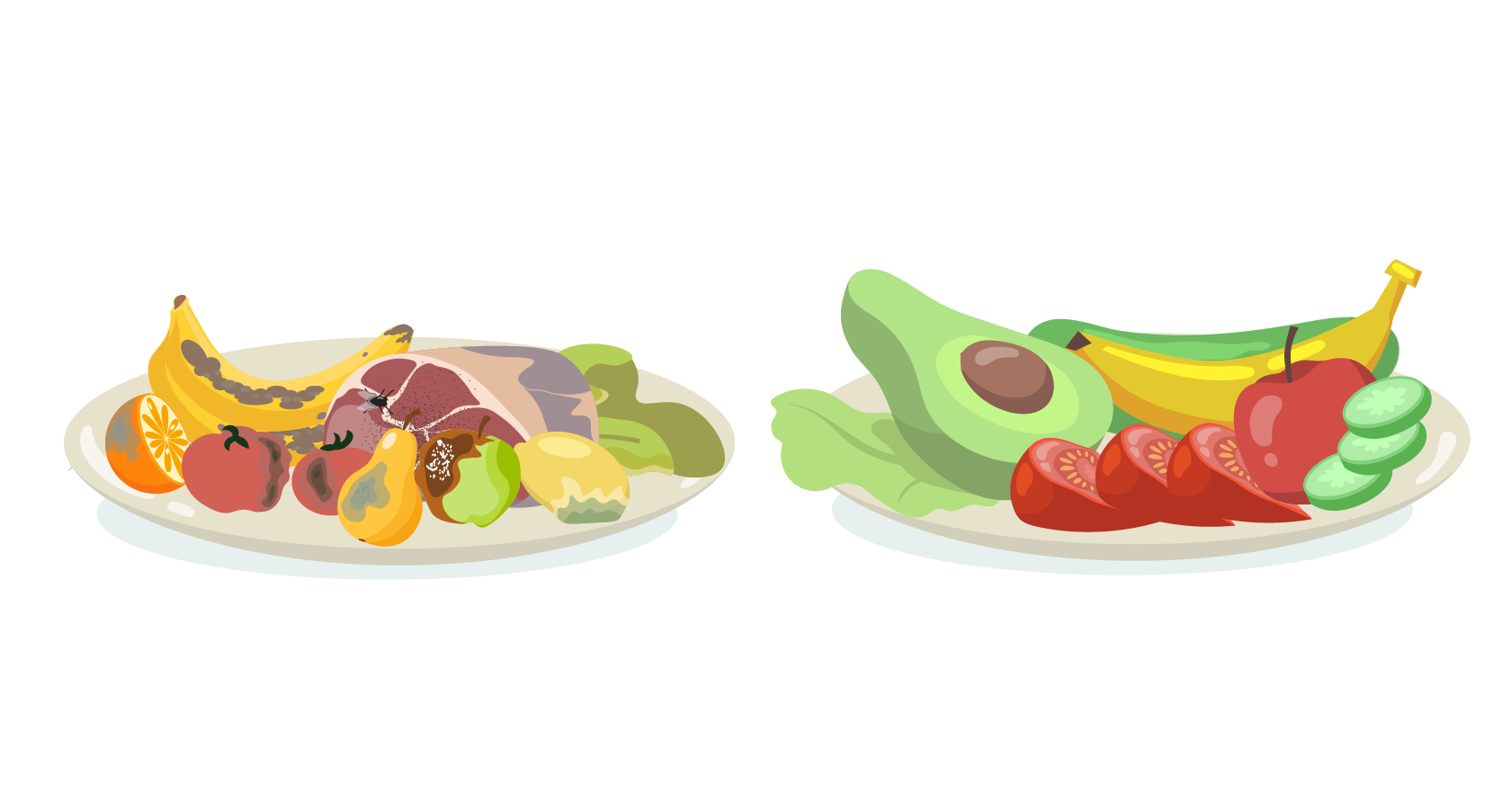

For example, perishable and fast expired goods such as food, if stored for too long in the warehouse, the quality of the goods may decrease or even become unfit for consumption when they arrive at the store.

Read more: Tips for maintaining product quality in the warehouse so that it is always excellent

Other benefits of inventory management:

- Inventory control

- Anticipating a shortage of stock (understock)

- Anticipating sudden order requests

- Easing the tracking of in-and-out stock

- Minimizing the risk of missing stock

The key to this inventory management is to maintain stock reasonably, thereby reducing the risk of loss.

Proper inventory management can help optimize the use of resources more efficiently and anticipate consumer demand. So, take a look and take note of the tips below!

Management Inventory Tips

1. Always Monitor Inventory Level

Neither overstock, shortage, nor even out-of-stock is great for business.

Storing excess stock can increase the risk of losses such as declining quality and expiration. On the other hand, running out of stock when there is high demand can disappoint customers and make them switch to another.

To avoid such problems, maintaining the optimal reorder level is the solution. The inventory level is the minimum amount of stock for each item that is used as a benchmark for restocking. Therefore, if the amount of your stock is less than the inventory level, you must immediately reorder.

Read more: The importance of product availability in stores

2. Maximize Warehouse Layout

Warehouses are often considered storage places only, so the layout is often neglected. However, a random warehouse layout can disrupt the in-and-out of goods flow. Apply some of these tips to your warehouse:

- Create a product layout with ABC Analysis. Place the best-selling products in the most accessible or closest to the packaging area.

- Separate new and old stock. Put the stock with the closest expiry date in the earliest order to get it out first.

- Provide a code for each item. For example, product A has ten colours of variations. Put the same coloured product into one box, then label it according to the colour.

- Place according to the item’s size. For example, place large, hard-to-reach items near the warehouse’s main door, then put the small, easy-to-reach items in the inner area.

- Give space between piles of items. Make sure there is space left to make it easier when picking things up.

Read more: The importance of store planogram to maximize sales

3. Use the FIFO FEFO Method

The FIFO (First-In-First-Out) method is the most commonly used method for retailers and wholesalers. As the name implies, this method prioritizes the order of goods coming out according to the order they are coming in. Therefore, the first product that goes in must go out first, too. This method is often used in the fashion industry due to rapid trend changes or in products with fragile packaging, which can be broken if stored too long.

Read more: Tips for Managing Stock in the Warehouse

The FEFO (First-Expired-First-Out) method is similar to the FIFO method. The difference is that this method prioritizes products with the fastest expiry date to sell or go out first. No need to pay attention to which items came in first. This method is usually used by the pharmaceutical industry, such as drugstores, or the food & beverage industry because the product has a short shelf life or spoils quickly.

These two methods ensure that the product that customers get is a product that is worth selling and still has a faraway expiry date.

4. Do Stock Taking Routinely

The difference between the number of stock items on record and the physical number of items in the warehouse is still the most common problem encountered in almost all business fields. It can happen because of lost, damaged, or even expired goods in the warehouse that are not detected when tracked from the records alone.

“How do we prevent stock differences?”

Regular stock-taking is one solution that you can try!

Stock taking is a physical verification of the quantity and quality of stock items and matching them with stock data in the company’s system. They are generally done at the end of the year, every three months, every six months, or even monthly, depending on business needs.

Purpose of stock-taking:

- Prevent out-of-stock or overstock

- Minimize the stock being expired in the warehouse before getting sold

- Predict the right time to restock

Read more: How to do an effective stock taking

5. Use Inventory Management System

Good inventory management must be able to accurately monitor the movement of goods and information related to inventory levels in real time, to prevent stock shortage. However, doing this is not easy, especially if you do it manually. Besides being inefficient, it will also make it difficult for you to optimize inventory management.

The inventory management system will make it very easy for you!

Read more: Special Offer for Distributors: #1 All-in-One App

Distri inventory management systems help you manage and monitor the movement of goods, maintain inventory level balance, create real-time inventory reports, and even predict your inventory needs. As a result, inventory management becomes more optimal, effective, and efficient. In addition, automation helps save a lot of time, money and effort.